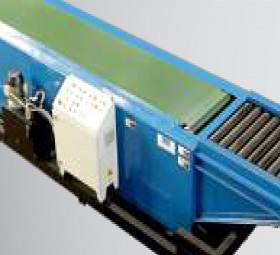

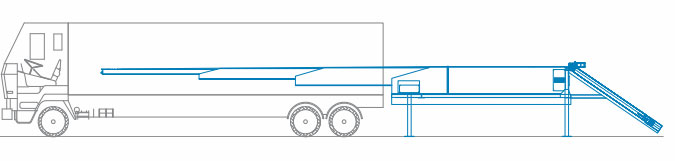

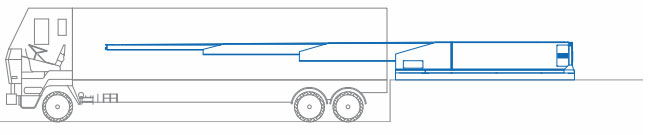

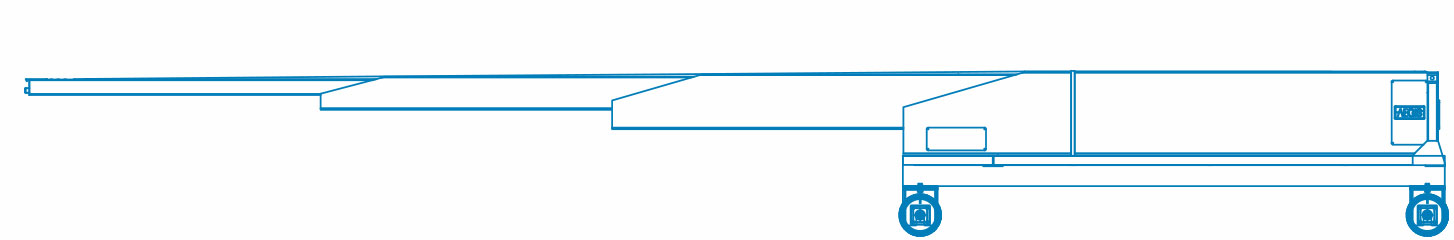

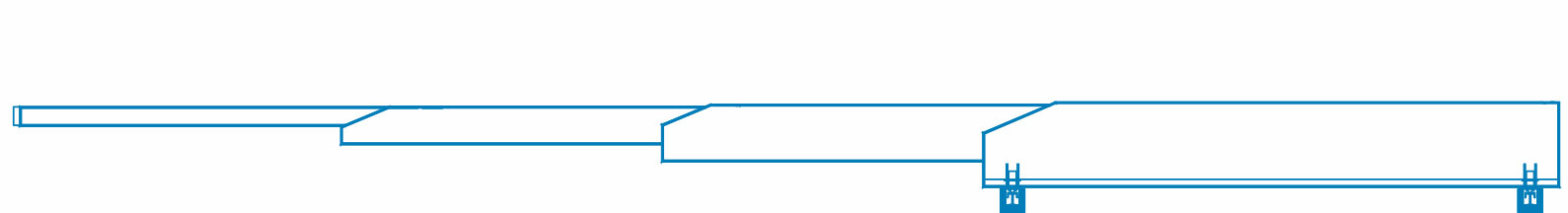

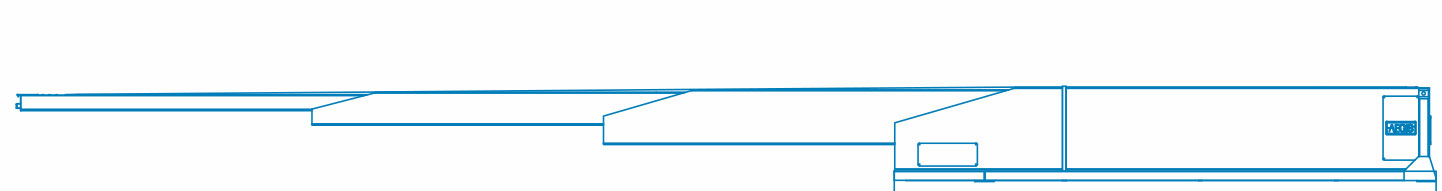

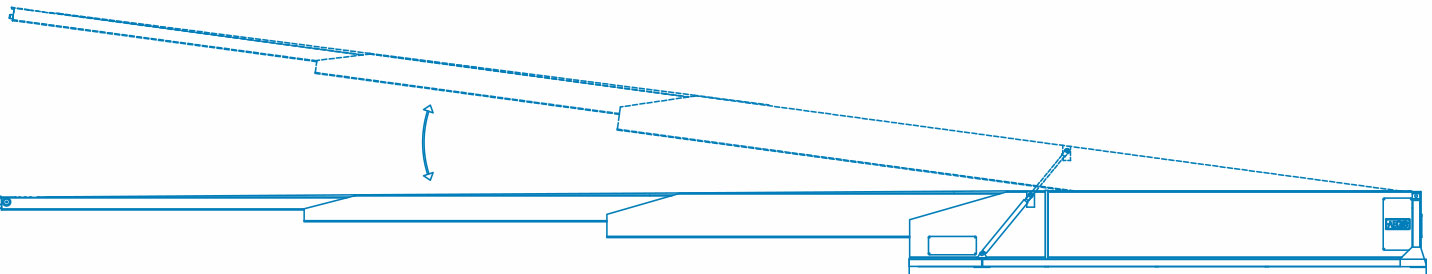

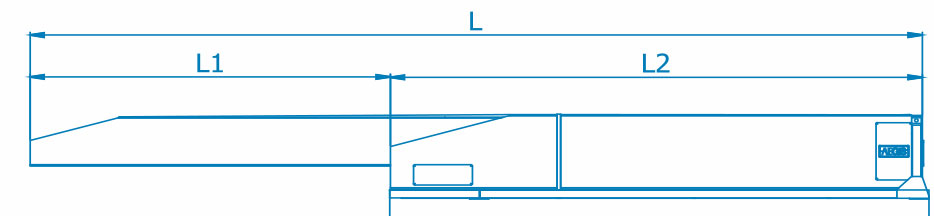

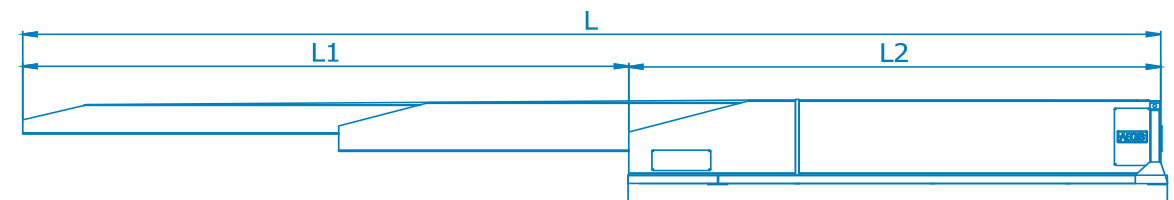

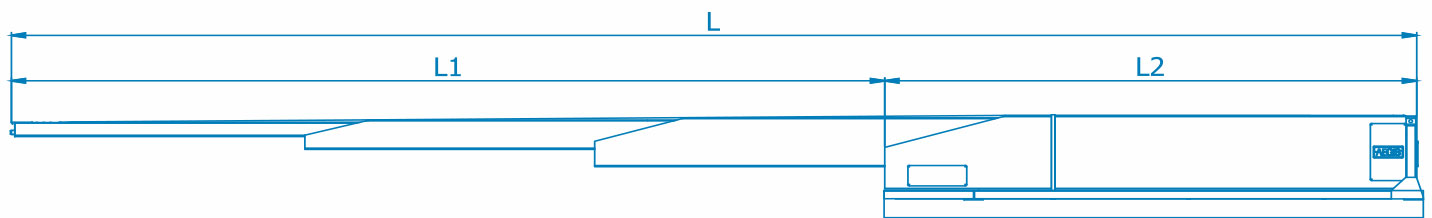

Foreseeing growing need for mechanizing truck/ container loading, telescopic conveyors were introduced for mechanizing loading and unloading capability – right to the front of container/truck for high volume dispatch and Telescopic conveyors are conceived and designed in-house and are continuously improvised to offer reliable and trouble free operation. Several version and options are conceptualized keeping in mind diverse requirement of end users.